Downloads

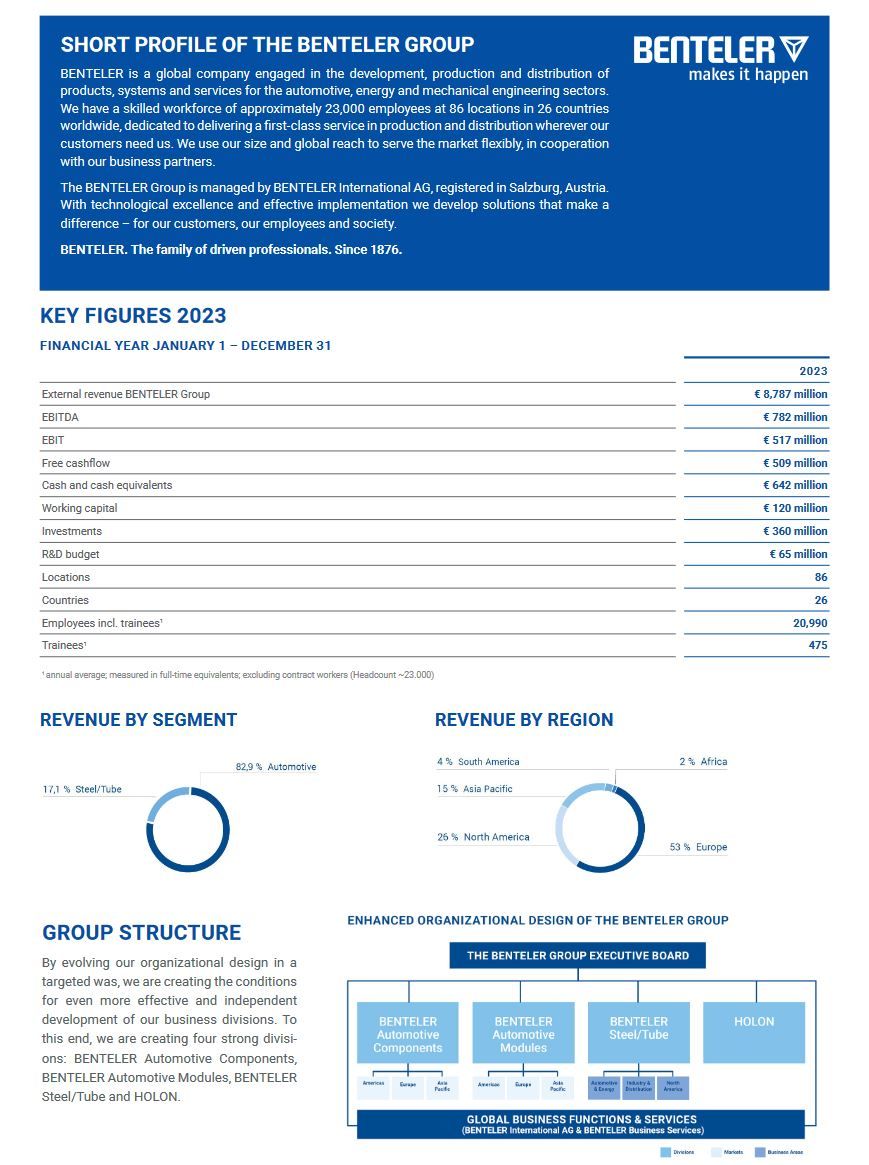

BENTELER Group

Company Fact Sheet

Company presentation

Annual report

The BENTELER Code of Conduct | 4,21 MB

BENTELER Automotive Policy | 132 KB (EN)

BENTELER Automotive Policy | 132 KB (PT)

Compliance at BENTELER | 525 KB

Annual Reports

Non-financial Reporting

Sustainability Report 2022 | 5,4 MB

Sustainability Report 2021 | 5,2 MB

Sustainability-Update 2020 | 1,2 MB

Sustainability-Update 2019 | 1,2 MB

Sustainability-Update 2018 | 1,8 MB

Sustainability Report 2017 | 1,2 MB

Sustainability-Update 2016 | 3,3 MB

Sustainability Report 2015 | 5,2 MB

BENTELER Automotive Certificates

Quality Management IATF 16949, 2021-2024, Porto Real

Quality Management IATF 16949, 2021-2024, Campinas

Quality Management IATF 16949, 2022-2025, Puebla Stamping

Quality Management IATF 16949, 2021-2024, Hagen

Quality Management IATF 16949, 2021-2024, Spartanburg

Quality Management IATF 16949, 2023-2024, Holland

Quality Management IATF 16949, 2022-2024, Puebla Assembly

Quality Management IATF 16949, 2022-2025, Joinville

Quality Management IATF 16949, 2022-2025, Sao Caetano

Quality Management IATF 16949, 2024-2027, Talle

Quality Management IATF 16949, 2024-2027, Warburg

Quality Management IATF 16949, 2024-2027, Kleinenberg/Lichtenau

Quality Management IATF 16949, 2021-2024, BENTELER Lightweight Protection

Quality Management IATF 16949, 2024-2027, Schwandorf

Quality Management IATF 16949, 2021-2024, Saarluis

Quality Management IATF 16949, 2021-2024, Düsseldorf

Quality Management IATF 16949, 2024-2027, Eisenach

Quality Management IATF 16949, 2021-2024, Skultuna

Quality Management IATF 16949, 2021-2024, Raufoss

Quality Management IATF 16949, 2021-2024, Burgos

Quality Management IATF 16949, 2021-2024, Vigo

Quality Management IATF 16949, 2021-2024, Valencia

Quality Management IATF 16949, 2021-2024, Palencia

Quality Management IATF 16949, 2021-2024, Palmela

Quality Management IATF 16949, 2024-2027, Mór

Quality Management IATF 16949, 2021-2024, Września

Quality Management IATF 16949,2021-2024, Malacky

Quality Management IATF 16949, 2021-2024, Stráž nad Nisou

Quality Management IATF 16949, 2024-2027, Jablonec

Quality Management IATF 16949, 2024-2027, Rumburk

Quality Management IATF 16949, 2022-2025, Klášterec

Quality Management IATF 16949, 2021-2024, Corby

Quality Management IATF 16949, 2021-2024, Gebze

Quality Management IATF 16949, 2021-2024, Martorell

Quality Management IATF 16949, 2021-2024, Vitoria

Quality Management IATF 16949, 2023-2026, 0702 Shenyang

Quality Management IATF 16949, 2021-2024, 0703 Wuhu

Quality Management IATF 16949, 2021-2024, 0706 Shanghai Jiading

Quality Management IATF 16949, 2021-2024, 0711 Shanghai Huizhong

Quality Management IATF 16949, 2024-2027, 0712 Changchun

Quality Management IATF 16949, 2021-2024, 0714 Fuzhou

Quality Management IATF 16949, 2021-2024, 0715 Shanghai

Quality Management IATF 16949, 2021-2024, 0717 Chongqing

Quality Management IATF 16949, 2021-2024, 0718 Tianjin

Quality Management IATF 16949, 2021-2025, 0739 Jian'an Chongqing

Quality Management IATF 16949, 2021-2025, 0758 Tianjin Plant II

Certificate ISO 14001, 2023-2026, Grand Rapids

Certificate ISO 14001, 2022-2026, Spartanburg

Certificate ISO 14001, 2021-2024, Holland

Certificate ISO 14001, 2022-2025, Puebla Stamping

Certificate ISO 14001, 2024-2027, Puebla Assembly

Certificate ISO 14001, 2021-2024, Joinville

Certificate ISO 14001, 2021-2024, Porto Real

Certificate ISO 14001, 2021-2024, Campinas

Certificate ISO 14001, 2021-2024, Sao Caetano

Certificate ISO 14001, 2022-2025, Skultuna

Certificate ISO 14001, 2022-2025, Raufoss

Certificate ISO 14001, 2022-2025, Malacky

Certificate ISO 14001, 2022-2025, Liberec, Straz nad Nisou

Certificate ISO 14001, 2022-2025, Jablonec

Certificate ISO 14001, 2022-2025, Chrastava

Certificate ISO 14001, 2022-2025, Rumburk

Certificate ISO 14001, 2022-2025, Klasterec

Certificate ISO 14001, 2024-2027, Germany

Certificate ISO 14001, 2023-2025, 0702 Shenyang

Certificate ISO 14001, 2022-2025, 0703 Wuhu

Certificate ISO 14001, 2022-2025, 0706 Shanghai Jiading

Certificate ISO 14001, 2021-2024, 0711 Shanghai Huizhong

Certificate ISO 14001, 2022-2025, 0712 Changchun

Certificate ISO 14001, 2021-2024, 0714 Fuzhou

Certificate ISO 14001, 2021-2024, 0715 Shanghai

Certificate ISO 14001, 2022-2025, 0717 Chongqing

Certificate ISO 14001, 2022-2026, 0718 Tianjin

Certificate ISO 45001, 2022-2025, Skultuna

Certificate ISO 45001, 2022-2025, Raufoss

Certificate ISO 45001, 2022-2025, Jablonec

Certificate ISO 45001, 2022-2025, Chrastava

Certificate ISO 45001, 2022-2025, Rumburk

Certificate ISO 45001, 2022-2025, Klasterec

Certificate ISO 45001, 2022-2025, Czech Republic

Certificate ISO 45001, 2023-2024, Germany

Certificate ISO 45001, 2023-2025, 0702 Shenyang

Certificate ISO 45001, 2022-2025, 0703 Wuhu

Certificate ISO 45001, 2022-2025, 0706 Shanghai Jiading

Certificate ISO 45001, 2021-2024, 0711 Shanghai Huizhong

Certificate ISO 45001, 2022-2025, 0712 Changchun

Certificate ISO 45001, 2021-2024, 0714 Fuzhou

BENTELER Steel/Tube Certificates

BST Corporate Certificate ISO 9001 | 1,6 MB

BST Shreveport Certificate ISO 9001 | 295 KB

Plant Paderborn - Quality Management IATF 16949 | 0.2 MB

Plant Rothrist - Quality Management IATF 16949 | 0.2 MB

Plant Dinslaken - Quality Management IATF 16949 | 0.2 MB

Plant Lingen - Quality Management IATF 16949 | 0.2 MB

Plant Schloss Neuhaus - Quality Management IATF 16949 | 1.6 MB

Plant Schwandorf - Quality Management IATF 16949 | 0.2 MB

EN ISO 14001 and EN ISO 50001 | 33 KB

Plant Dinslaken - 41 API 5CT | 1.211 KB

Plant Dinslaken - 65 API 5CT | 1.398 KB

Plant Dinslaken - 65 API 5DP | 1.145 KB

Plant Dinslaken - 65 API 5L | 1.384 KB

Plant Paderborn - API 5CT | 780 KB

Plant Paderborn - 41 API 5L | 1.369 KB

Plant Schloss Neuhaus - API 5CT | 469 KB

Plant Schloss Neuhaus - API 5L | 430 KB

Plant Shreveport - API 5L | 337 KB

Plant Shreveport - API 5CT | 323 KB

Plant Shreveport - API Q1 | 82 KB

AEO Certificate Type C | 385 KB

Plant Dinslaken – EN 10210-1:2006 | 2,5 MB