BENTELER

SMARTCUT®

Efficient. Sustainable. Machinable

Free-cutting

steel tubes

BENTELER SMARTCUT® combines the advantages of highly machinable free-cutting steels with the geometric benefits of a tube, optimizing the machining process. This innovative combination often results in material savings of over 50% compared to bar steel, all while maintaining excellent machinability.

With its integrated supply chain from the steel mill to the seamless tube, BENTELER is able to develop customized steel grades as innovative SMARTCUT® variants.

Benefits at a glance

More aboutBENTELER SMARTCUT®

Efficiency

Leverage innovative materials to boost productivity and significantly reduce your material, processing and manufacturing costs.

- With free-cutting steel, you can reduce machining costs by up to 40% compared to standard materials.

- Using tubes eliminates processing steps such as drilling.

- Tubes improve material utilization, often resulting in material savings of over 50% compared to bar steel.

Take the lead in sustainability. Benefit from a reduced carbon footprint, potential weight saving, and minimized production waste.

- Using electric steel reduces CO₂ emissions by more than 70% compared to the blast furnace route.

- Comply with all EU REACH regulations by using lead-free materials, ensuring long-term environmental sustainability.

- Optimize lightweight potential: Strength-optimized materials can reduce the dimensions of machined parts, saving both CO₂ and costs.

Machinability

Combine the advantages of highly machinable free-cutting steel with the benefits of a tube, optimizing your manufacturing process.

- Highly machinable free-cutting steels prevent unwanted chip formation, increasing the productivity of your manufacturing process.

- These steels can extend tool life by up to 400%.

Steel tubes with

a plus in sulfur

Better machinability, greater cost-effectiveness

Steel tubes with

a plus in sulfur

Better machinability, greater cost-effectiveness

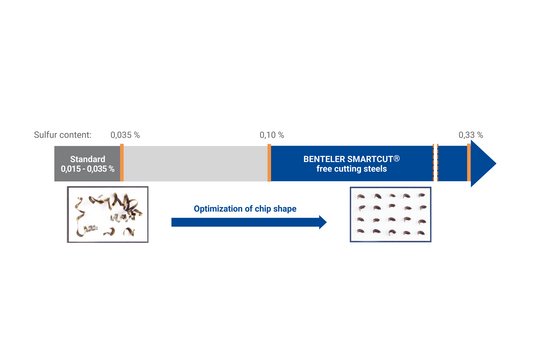

BENTELER SMARTCUT® is the first tube manufactured from free cutting steel. Our tube solutions are optimally suited as a primary material for machining. The minimum sulfur content of 0.10% in BENTELER SMARTCUT®, which is around three to ten times higher than the usual 0.015 to 0.035% for machined tubes, means that our customers can process tubes better and at lower cost. The material concept allows faster machining and, thanks to the stability, without human interaction. Machining costs can therefore be reduced by up to 40% compared with standard steels.

Free cutting

steel tubes

Prevent tangled swarf, improve chip formation, increase process stability

Free cutting steel’s optimized material properties offer clear advantages in machining operations. As a result, our free cutting steel tubes can solve typical machining challenges such as:

- Tangled swarf due to lack of or insufficient chip breaking.

- High tool wear

- Machining processes that are not stable and require frequent operator intervention

- Different processing behavior between different material batches

BENTELER SMARTCUT® can stabilize turning processes as well as increase tool service life by up to 400%.

Innovative solutions for diverse applications

Innovative solutions for diverse applications

The product line of both hot-rolled as well as cold-drawn seamless steel tubes offers optimized designs for various applications. Economical machining can thereby be achieved in both smaller quantities and large-scale series production.

Individually

customizable

With BENTELER SMARTCUT®, we provide seamless tube solutions tailored for machining companies, machine builders, and precision component manufacturers. Utilizing free-cutting steel, we can produce turned parts and customize products to meet specific customer requirements through an integrated supply chain from the steel mill to the seamless tube.

In collaboration with our customers, we develop tailored solutions, adjusting the material properties of the free-cutting steel to meet individual needs. Plus, together with our customers, we develop custom-fit solutions and can tailor the material properties of the free cutting steel to individual needs.

In addition, the tubes can be supplied with customized processing, such as a machined inner surface or pre-cut as a short length. Our tubes can be supplied with heat treatment, for example quenched and tempered.

CARBON FOOTPRINT STEEL

(kg CO2/metric ton of steel)

Are you FIT FOR 55?

Are you FIT FOR 55?

With our tubes made from CO₂-reduced free cutting steel, we help you to comply with the specifications of the EU Green Deal. BENTELER SMARTCUT® tubes are guaranteed lead-free in accordance with the EU REACH Regulation and protect the environment.

In addition, steel production in our own electric steel mill generates 75% less CO₂ than the blast furnace route often used for bar steel. CO₂ emissions can be significantly reduced further by using green electricity.

This is how we can help you achieve your climate targets.

Download

Would you like more information about our SMARTCUT® tubes? Download our product information.