Hot & Cold

Forming

Higher stiffness with lower weight, higher quality and lower production costs.

BENTELER – The pioneers

The demands on manufacturing for modern vehicles are diverse and complex, not least when it comes to forming components.

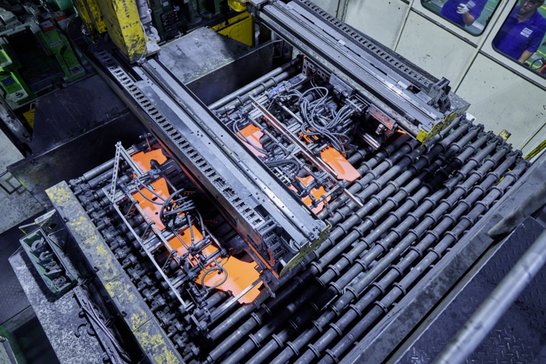

We offer products worldwide in all materials, in cold and hot-formed carbon steel, in stainless steel and aluminum, in sheet metal and extruded profiles. When it comes to forming technologies, we have an unparalleled track record.

Today, we continue to research and develop innovative techniques, for example cutting during the forming process, thereby removing the need for a dedicated laser cutting station. Our competence in aluminum forming extends from the basic material including advanced 7000 series alloys to finished goods. This gives us a unique capacity to fulfill your most demanding requirements.

CAN YOU MAKE COMPLEX TORSION PROFILES SUCH AS TWIST BEAM AXLES QUICKLY AND COST EFFECTIVELY?

With BENTELER, you can.

Because our development approach using our patented 3D U-O forming technology is unique in the industry. It allows us to produce complex trapezoidal torsion tube forms faster and more cost effectively. That´s good news for us, better news for our customers!

At BENTELER, we are proud of our long history...

At BENTELER, we are proud of our long history...

…as pioneers in hot forming. We were the first company to develop the technology and produce hot-formed structural components for use in the automotive industry. Today, we’re one of the three most important global partners. By the way, we’re also leaders in cold forming.

Holistic planning,

global manufacturing

Together with our customers and the global production network, we set standards. Globally. Because we operate over 60 hot forming lines and almost 200 cold-forming presses around the world. And thanks to centralized planning, our production systems are completely standardized.

Formed to deform

Formed to deform

At our state-of-the-art aluminum plant in Raufoss, Norway we form innovative front and rear crash boxes from aluminum profiles. The deformable systems absorb more energy than most conventional solutions while making the vehicle lighter. That helps protect the passengers – and the environment. And because we use induction heating for the aluminum billets, we’re reducing CO₂ emissions from the plant at the same time.

Did you know…

Did you know…

…that our production is simulated in 3D to ensure fast and cost-efficient processes? Using the latest simulation techniques we test how metal reacts when it’s formed. This allows us to provide you with accurate performance data about components before they go into production. For example, matched data for better crash simulation before the design even leaves the drawing board.