THERMAL & TUBULAR

Excellence in Engineering Solutions

Tight spaces, high pressures, extreme temperatures: the demands of engine and exhaust systems found in modern vehicles call for ingenious solutions; a combination of first-class engineering and metal-processing competence. We are the world leader in manufacturing fuel manifolds and lines for high-pressure injection systems and one of the leading suppliers of exhaust gas recirculation systems. We are also a global supplier of exhaust manifolds, both in assembled design as well as component form. Plus, we offer innovative solutions for heat recovery for internal combustion engines, as well as for hybrid drives and electric vehicles.

Our development and production know-how and focus on technologies for the reduction of CO2 and pollutant reduction technologies make us your ideal global development partner for modern mobility.

PRODUCT FAMILIES

Whether it’s gasoline, diesel, hybrid or electric driven, our extensive range of innovative engine and exhaust systems cover just about any need.

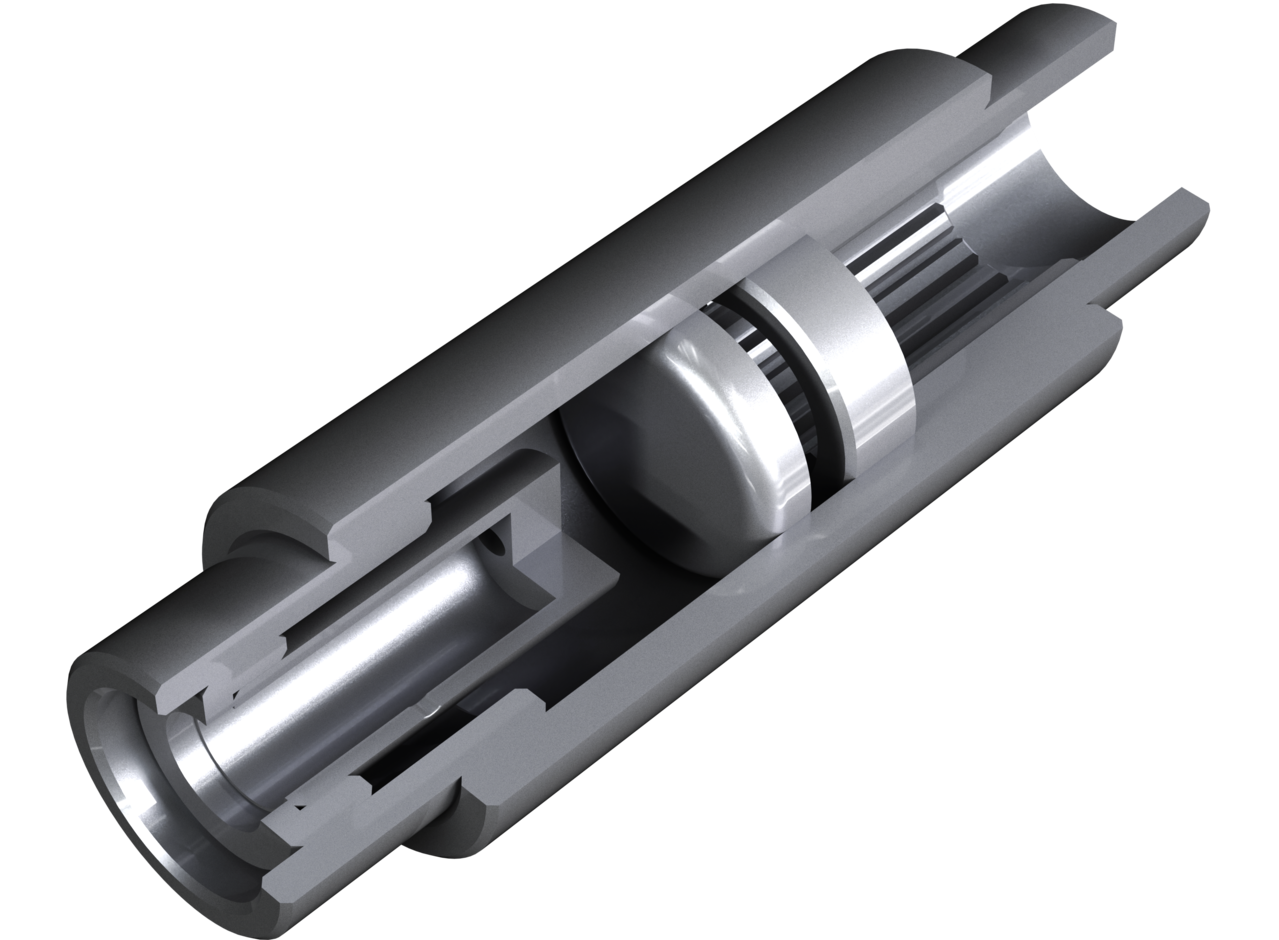

Rotor Shaft

Welding, brazing, tube forming, machining – by combining our process know-how and BENTELER’s in-house green steel tube production, we provide rotor shaft solutions with reduced material requirements and best-in-market CO2 footprint.

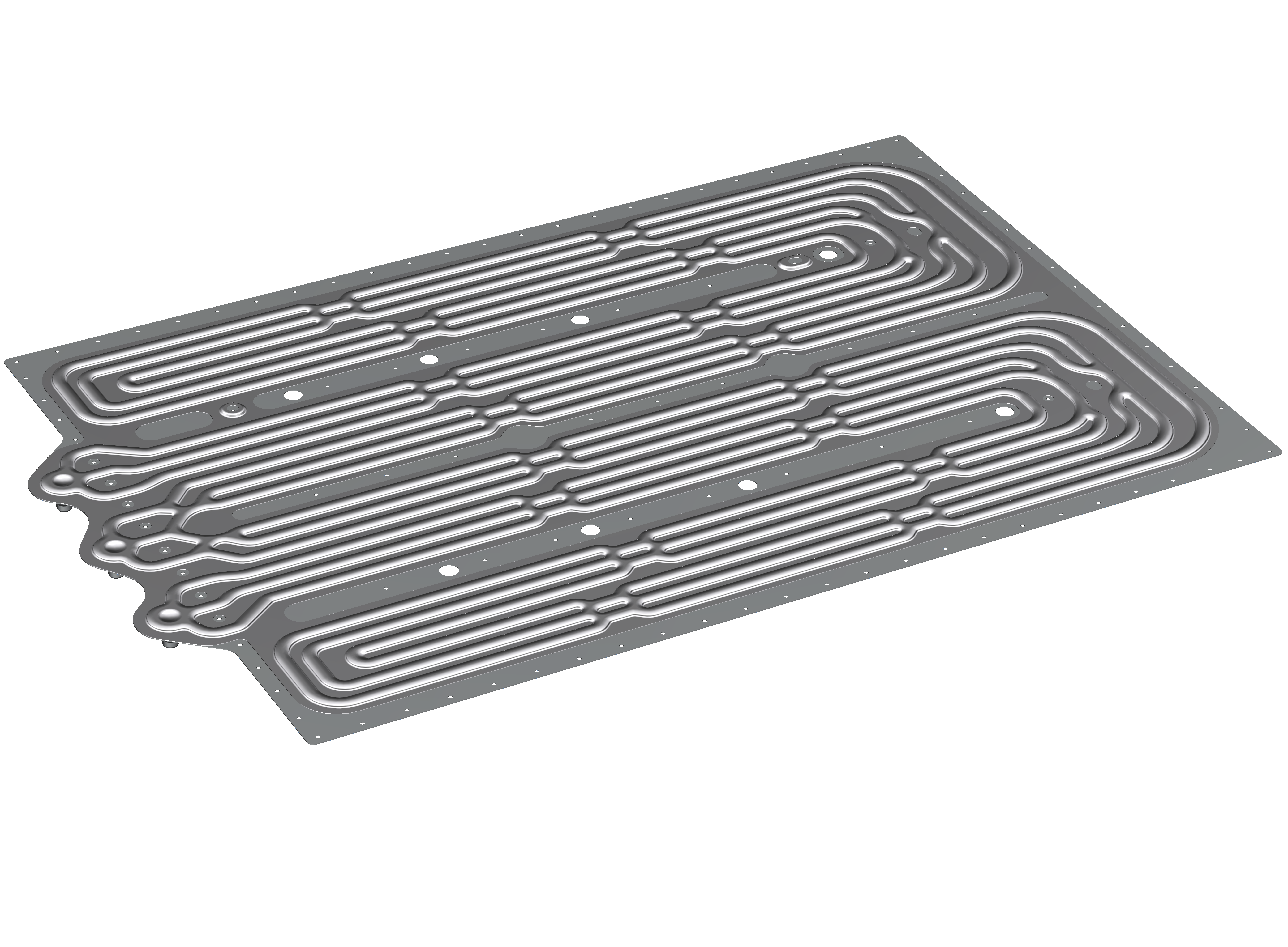

Battery Cooling Plate

With our innovative and patented Press Brazing process, we produce battery cooling plates that combine reduced wall thickness with optimized strength. In addition to weight reduction, our Press Brazing process uses 100% green electricity.

Battery Strut

Geometry, weldability, strength, toughness. We're well versed in combining material properties. With our innovative BTR165® material, for example, we can substitute a square profile using our round tube with 22% less wall thickness. This contributes to a significant weight reduction of 39% while offering the same crash performance. Plus, our in-house green steel tubes improve the CO2 balance.

After-treatment systems

Our exhaust gas cleaning systems are optimized for installation space and performance to allow the largest possible catalytic converters to be fitted in narrow engine installation spaces. They are further optimized for flow and temperature, ensuring maximum utilization of the catalytic converter area to minimize pressure and heat losses in the system.

Air gap insulated turbine housings

Our air gap insulation reduces thermal losses compared with cast iron construction for better efficiency and start-up behavior. This leads to up to 38ºC higher catalyst inlet temperatures, which leads to emission reduction. Plus, reduced heat radiation allows a major reduction in heat shield weight.

Dual-wall exhaust manifolds

Available as air gap or fiber mat insulation offering lower thermal losses than cast iron construction for better efficiency and start-up behavior. This leads to up to 38ºC higher catalyst inlet temperatures, which leads to emission reduction. Plus, reduced heat radiation allows a major reduction in heat shield weight.

Gasoline particulate filters

BENTELER offers extensive manufacturing competence across the globe in high-precision integration of precious metal-coated ceramic or metal catalytic converters. Ideal for installation in confined spaces, our filters are optimized for flow to minimize pressure losses, thereby maximizing filter utilization.

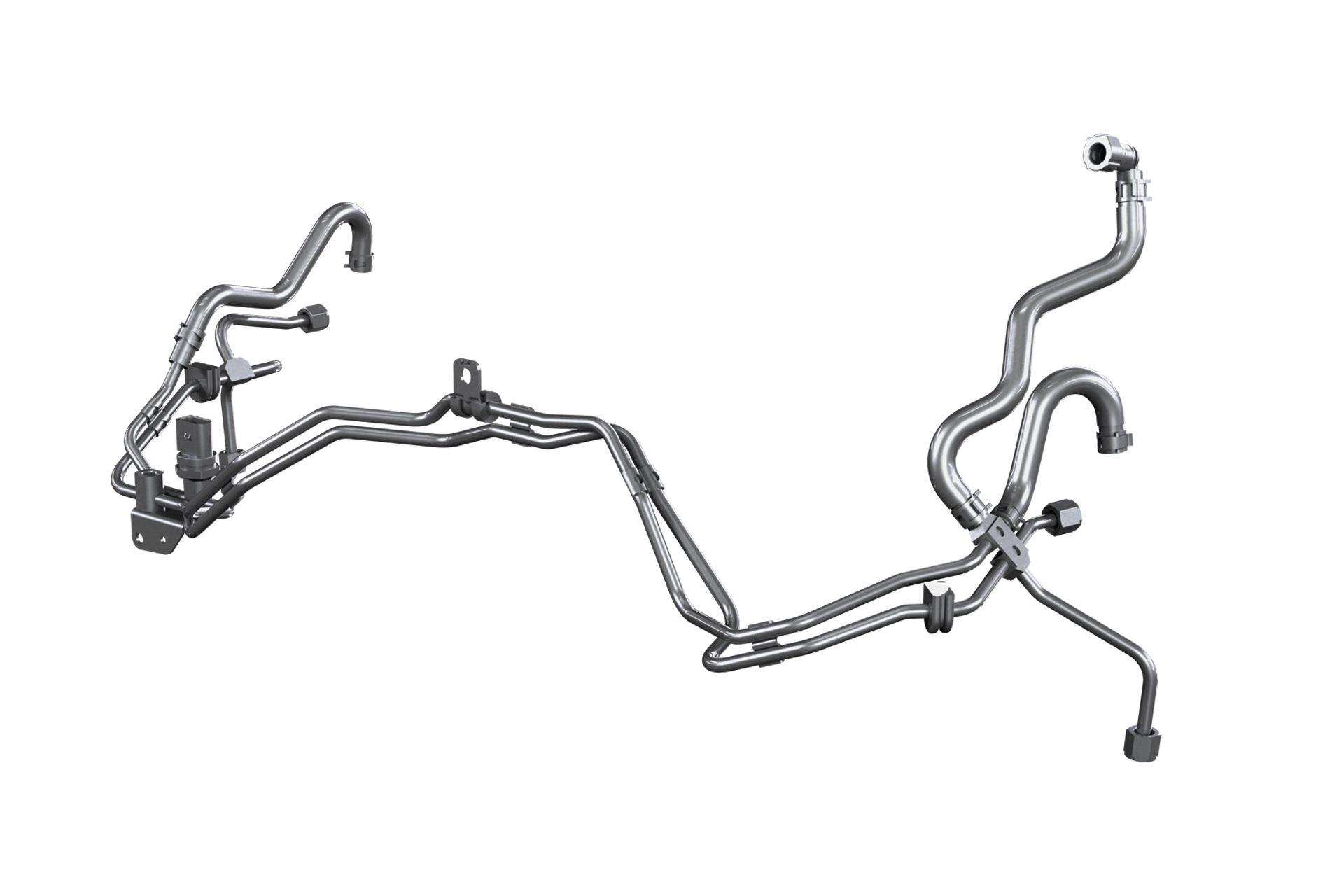

Air-water-oil

BENTELER supplies a range of steel and stainless steel tubes for air, water and oil systems in engine applications. These draw on our metal processing expertise and feature complex bending and forging processes, including tube assembly, often with hydrogen furnace brazing with copper or nickel solder.

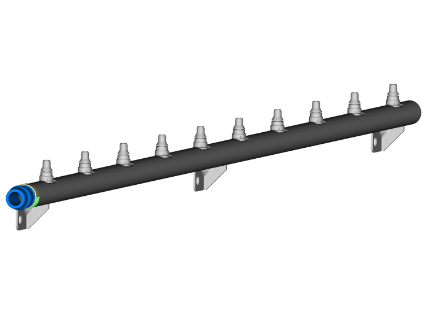

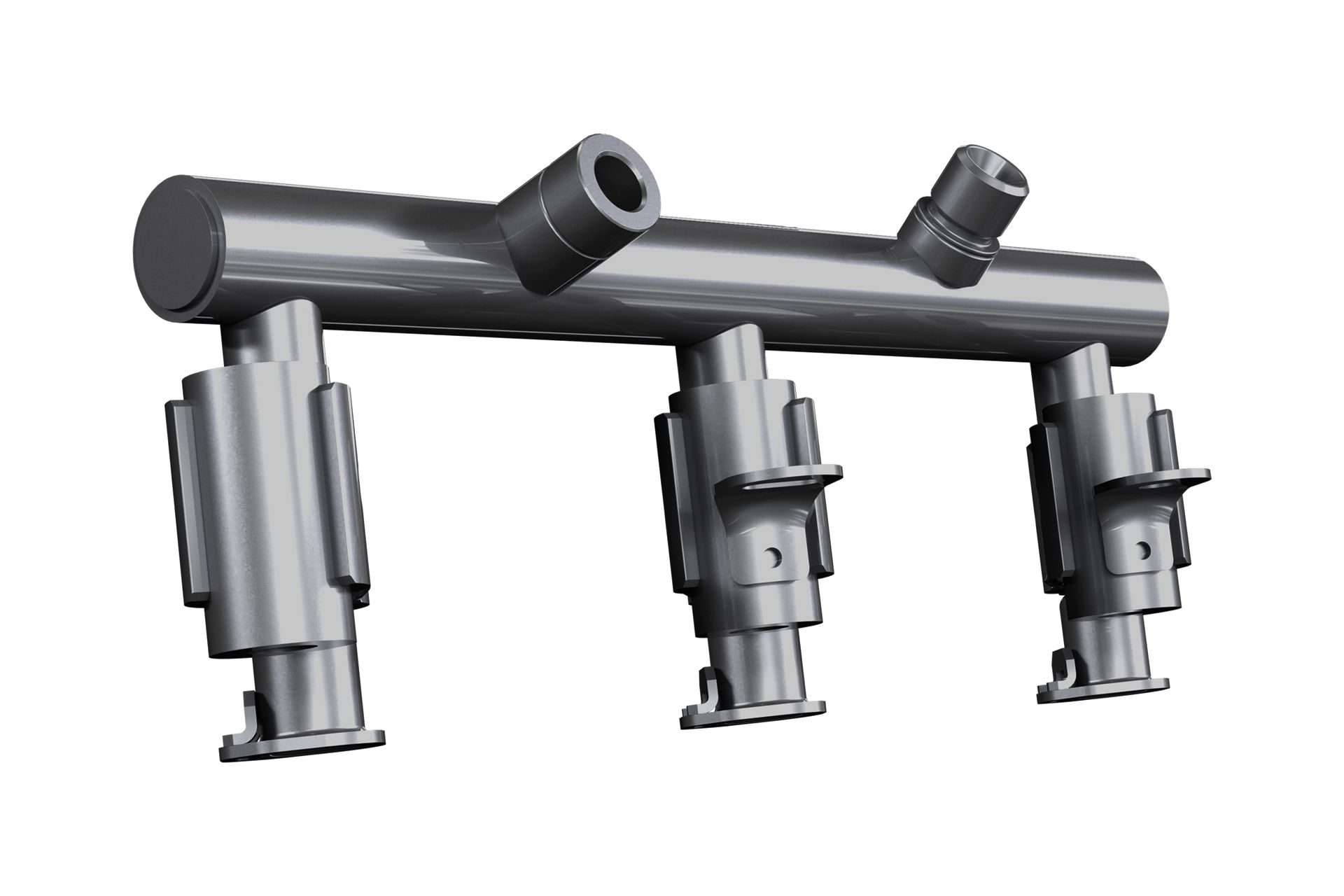

Fuel rail assemblies

We are a leading supplier of brazed stainless steel high pressure fuel rail assemblies, with integrated cast, forged and deep-drawn components. We offer global manufacturing and full in-house product and process development capabilities. We fulfil the highest standards with, for example, fully automated injector and sealing package assembly in clean room conditions.

Exhaust gas recirculation

BENTELER is one of the world’s leading suppliers of exhaust gas recirculation systems. From concept to series production, we are a full-service provider. Our products feature high-performance cooling with stainless steel construction, optimized internal geometry for maximum heat transfer and high thermal durability for high-performance applications.

Electrically heated catalytic converter

Suitable for all cars with internal combustion engines, our electrically heated catalytic converters ensure almost 100 % pollutant removal during cold starts. Manufacturing the innovative catalysts calls for a high level of expertise in forming and high-temperature brazing – our core competences.

Low and high pressure fuel lines

Over 7 million fuel distributor rails produced globally per annum! That makes us market leaders in high pressure manifolds. Our stainless steel solutions feature complex bending and direct upset forging of the ball bushings. Our forged fuel distributor rails allow higher injection pressures compared to conventional brazed solutions, thereby reducing pollutant emissions.

Forged and machined stainless steel manifold rails

Our stainless steel injection / manifold rails are suitable for injection pressures in excess of 350 bar. With our unique fully-automated machining concept, all machining operations are completed in a single clamping. We also offer fully automated fuel module assembly for piezo injectors with a complex sealing package.